Liquid food pouch packaging has revolutionized the way we store and transport liquid-based products like juices, milk, sauces, and soups. This flexible, compact packaging option allows manufacturers to deliver liquids efficiently and cost-effectively. Unlike traditional glass or plastic bottles, liquid pouches are lightweight, flexible, and easy to transport. They can be sealed tightly, offering excellent protection against contamination and spoilage, while ensuring freshness.

Whether you're enjoying a convenient drink from a pouch or using a pouch for condiments, these packages offer greater shelf life and are less prone to breaking, unlike glass alternatives. Their ability to be resealed and their small size also make them the perfect on-the-go solution for busy consumers.

The materials used in liquid pouch manufacturing play a crucial role in preserving the quality of the contents. A variety of materials are typically used in the production of liquid food pouches, each chosen for its ability to maintain the integrity of the liquid inside.

• Polyethylene (PE): This material is often used for liquid food pouches due to its durability, flexibility, and resistance to moisture. It provides an excellent oxygen barrier, preventing spoilage.

• Polypropylene (PP): Lightweight and resistant to chemicals, PP is another popular material used for pouches that need to be heat-sealed.

• Aluminum Foil: In many liquid pouches, especially those for juices or dairy products, a layer of aluminum foil is included for its ability to block out light and oxygen. This is essential for extending shelf life and preserving the taste and nutritional value of the product.

• PET (Polyethylene Terephthalate): Known for its strength, PET is often used for the outer layer of liquid pouches. It provides excellent protection and gives the pouch a crisp, clean look.

• BPA-free Materials: Manufacturers increasingly choose BPA-free plastics to ensure that their pouches are safe for consumers and meet growing consumer demand for health-conscious packaging.

Each of these materials is carefully selected to ensure that the food remains fresh, safe, and easily consumable, with minimal environmental impact.

ML-2400 Multifunctional Liquid Bag Making Machines

Liquid pouches are produced through a highly sophisticated and automated process, thanks to advances in liquid pouch-making machines. These machines are designed to produce pouches in a fast, efficient, and cost-effective manner, catering to the high demand for liquid food packaging. The process typically includes the following stages:

• Film Unwinding: The first step in the manufacturing process involves unwinding large rolls of the chosen packaging material. The material is then fed into the machine for further processing.

• Shaping and Sealing: The machine uses heat to form and seal the pouch shape, usually through a combination of heat-sealing bars and specialized molds. The liquid pouch is shaped and the opening sealed to prevent leaks.

• Filling: Once the pouches are sealed and shaped, the machine fills them with the desired liquid. This step is often done using a filling machine, which ensures precision and avoids spillage.

• Final Sealing and Cutting: After filling, the pouches are sealed and cut to size. The sealing ensures that the liquid is securely contained, while the cutting ensures that each pouch is uniform and of the correct size.

• Printing and Labeling: Once the pouches are completed, they may be printed with branding, product information, and expiration dates. Some machines also incorporate automated labeling processes.

These machines enable high-speed production, making it easier for manufacturers to meet consumer demand while maintaining consistency in quality and appearance.

The adoption of liquid bag making machines has several key advantages for food manufacturers:

• Increased Production Efficiency: Liquid pouch making machines operate at high speeds, enabling manufacturers to produce large volumes of pouches quickly. This leads to cost savings and faster turnaround times.

• Consistent Quality: With automated processes, manufacturers can ensure that every pouch is produced to the same high standard. This reduces the risk of human error and ensures that each package is sealed tightly and securely.

• Customizable Designs: Liquid pouch making machines allow manufacturers to customize the shape, size, and features of the pouches. This flexibility helps brands differentiate their products and meet the specific needs of their customers.

• Cost-Effective: By reducing the amount of packaging material used and enhancing production speed, liquid pouch machines lower production costs. Additionally, liquid pouches themselves are generally cheaper to produce than rigid containers like bottles and jars.

• Sustainability: Many liquid pouch making machines are designed to work with eco-friendly materials, which aligns with growing consumer demand for sustainable packaging solutions. Liquid pouches also require less energy to produce compared to traditional glass or plastic packaging.

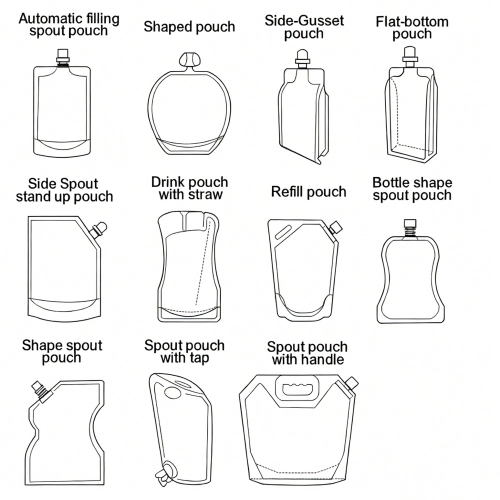

There are various types of liquid food pouches, each designed to meet specific needs based on the product inside and its intended use. Here are some of the most common:

Stand-Up Pouches: These pouches are designed with a bottom gusset, allowing them to stand upright on shelves. They are ideal for products like juices, soups, and sauces, as they provide excellent stability and visibility.

Flat Pouches: Flat pouches are typically used for products like milk and yogurt. They are easy to store and stack, making them an economical choice for high-volume distribution.

Spouted Pouches: These pouches have a small spout that allows for easy pouring of liquids. They are commonly used for juices, liquid food products, and baby food.

Retort Pouches: These are used for products that need to be heated to preserve freshness. Retort pouches are heat-resistant and can handle the high temperatures involved in sterilization processes, making them ideal for ready-to-eat meals, soups, and sauces.

Flexible Film Pouches: Often used for dairy products, flexible film pouches offer durability, lightweight storage, and a long shelf life. These pouches are especially useful for products that require controlled dispensing and minimal air exposure.

Each type of pouch offers unique benefits in terms of convenience, storage, shelf life, and branding opportunities.